Spot Welder Maintenance Guide

Published by Pro Line Systems in Informational · 23 March 2024

Tags: Spot, Welder, Maintenace, Guide, For, A, Trouble, Free, Machine

Tags: Spot, Welder, Maintenace, Guide, For, A, Trouble, Free, Machine

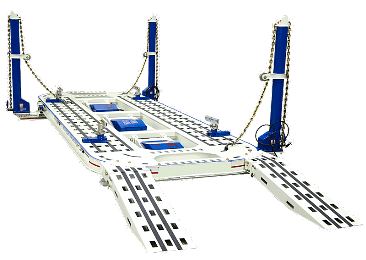

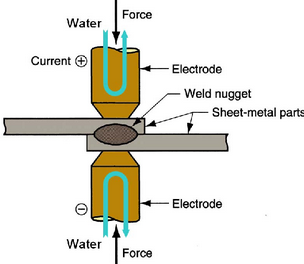

In the world of auto body repair, precision and efficiency are top priorities. To ensure seamless operations and top-notch results, maintaining your high-powered Liquid-Cooled or Non-liquid-cooled resistance spot welder is crucial. This sophisticated piece of equipment demands regular attention and care to keep it functioning at its best. In this guide, we'll walk you through step-by-step maintenance procedures to help you uphold the performance and longevity of your resistance spot welder.

"Everything In Life Requires Maintenance"

Your Spot Welder Is No Different.

Let's Dive In!

1. Understand Your Equipment:

Before diving into maintenance tasks, familiarize yourself with the components and operations of your resistance spot welder. Refer to the manufacturer's manual for detailed insights into its construction, functions, and maintenance requirements.

- By familiarizing yourself with the equipment, you can operate it effectively, identify maintenance needs promptly, and maximize its lifespan.

2. Regular Inspections:

Perform routine visual inspections to identify any signs of wear, damage, or abnormalities. Check for loose connections, worn electrodes, coolant leaks, and overall cleanliness. Address any issues promptly to prevent further damage or malfunctions.

- Routine inspections allow you to spot potential problems early, address them promptly, and prevent more significant issues from arising, ensuring uninterrupted workflow and consistent weld quality.

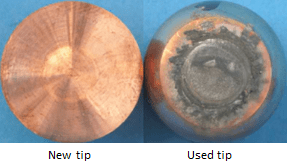

3. Electrode Maintenance: Very Important.

- Inspect electrodes regularly for signs of wear, such as deformation or pitting.

- Clean electrodes thoroughly to remove debris, oxidation, and spatter buildup.

- Replace worn or damaged electrodes following manufacturer guidelines.

- Ensure proper alignment and tightness of electrode holders to maintain consistent weld quality.

It is time to replace this electrode tip or dress it, or your

spot welds will fail.

- Electrode wear and contamination can compromise weld quality and consistency, affecting the structural integrity of repaired auto bodies.

- Proper electrode maintenance ensures consistent welding performance, prolongs electrode lifespan, and enhances the quality and durability of welds, ultimately contributing to safer and more reliable vehicle repairs.

4. Coolant System Maintenance:

- Monitor coolant levels regularly and top up as needed with the recommended coolant solution.

- Check for coolant leaks and repair or replace damaged hoses or fittings promptly.

- Clean or replace coolant filters to prevent clogging and ensure optimal cooling efficiency.

- Flush and replace coolant according to the manufacturer's recommended intervals to prevent corrosion and maintain thermal stability.

- Inadequate cooling can lead to overheating, thermal stress, and equipment failure, jeopardizing the welder and welded joints' integrity.

- Regular coolant system maintenance ensures efficient heat dissipation, prevents equipment overheating, and maintains stable welding conditions, preserving weld quality and prolonging equipment lifespan.

FYI: Clean Air: You should already know this, But, make sure you provide clean filtered compressed air not only to your Spot Welder but to all air driven tools. Inspect and maintain your air filtration systems and your air driven tools will reward you with best performance and longevity.

Add A Few Drops Of Oil To The Air Inlet:

Adding a few drops of oil to the air inlet of a squeeze-type liquid-cooled spot welder serves a specific purpose and is important for maintaining the equipment's functionality and longevity. Here's why:

Follow the manufacturer's documentation for the type of oil and the suggested schedule to do this.

- Resistance Spot Welders often incorporate pneumatic systems for various functions such as electrode actuation and cooling. The air inlet serves as a pathway for compressed air, which is crucial for powering these pneumatic systems. Adding a few drops of oil to the air inlet lubricates the internal components of the pneumatic system, ensuring smooth operation and reducing friction.

- Prevention of Corrosion: Air compressors used in industrial settings can introduce moisture into the pneumatic system. Moisture can lead to corrosion of metal components within the spot welder's pneumatic system, affecting its performance and potentially causing malfunctions. By adding oil to the air inlet, the oil forms a protective barrier against moisture, reducing the risk of corrosion and extending the lifespan of the welder.

5. Power Supply Maintenance:

- Inspect power cables, connectors, and insulation for any signs of wear, damage, or overheating.

- Test the integrity of electrical connections and grounding to ensure safety and optimal performance.

- Clean and maintain the power source unit as per manufacturer instructions to prevent dust accumulation and overheating.

- Make sure to have a qualified electrician install a heavy-duty commercial locking plug on the power cord and any extensions. If any plug accidentally detaches during spot welding it could damage the machine.

- Electrical faults or malfunctions pose significant safety hazards and can damage sensitive electronic components within the welder.

- Proper maintenance of the power supply unit ensures electrical safety, prevents downtime due to equipment failure, and safeguards against costly repairs or replacements.

6. Calibration and Performance Checks:

- Regularly calibrate the welder according to the manufacturer's specifications to maintain accuracy and consistency.

- Conduct performance checks by welding test pieces and inspecting the weld quality, ensuring it meets desired standards.

- Adjust settings as necessary to optimize weld parameters for different materials and thicknesses.

- Inaccurate calibration or incorrect weld parameters can result in defective welds, compromising structural integrity and safety.Regular calibration and performance checks ensure accurate weld settings, consistent weld quality, and compliance with industry standards, reducing the risk of rework and liability issues.

7. Safety Procedures:

- Prioritize safety by following all recommended safety protocols and guidelines during maintenance tasks.

- Use appropriate personal protective equipment (PPE), including gloves, eye protection, and protective clothing.

- Disconnect power sources and follow lockout/tagout procedures before performing maintenance or repairs.

- Neglecting safety protocols can result in accidents, injuries, or even fatalities, endangering both personnel and equipment.

- Adhering to safety procedures minimizes the risk of accidents, creates a secure working environment, and protects personnel from harm, fostering productivity and morale within the workshop.

8. Documentation and Record-Keeping:

- Maintain comprehensive records of maintenance activities, including inspections, repairs, and replacements.

- Note down any anomalies or issues encountered during maintenance for future reference and troubleshooting.

- Keep track of warranty information, service schedules, and contact details for technical support and spare parts procurement.

- Inadequate documentation can lead to oversight of maintenance tasks, compliance issues, and difficulty in troubleshooting equipment failures.

- Comprehensive record-keeping facilitates accountability, aids in tracking maintenance history, and provides valuable insights for optimizing maintenance schedules and practices, ultimately enhancing equipment reliability and performance.

9. Professional Service and Training:

- Engage qualified technicians for specialized maintenance tasks or repairs beyond your expertise.

- Invest in regular training and certification programs for you and your team to stay updated on the latest maintenance techniques and best practices.

- Lack of technical expertise or training can result in improper maintenance procedures, leading to equipment damage or suboptimal performance and compromised spot welds.

- Engaging qualified technicians and investing in ongoing training ensures competent maintenance practices, reduces the risk of errors or accidents, and promotes continuous improvement in equipment care and operation.

10. Continuous Improvement:

- Solicit feedback from operators and technicians regarding equipment performance and maintenance procedures.

- Implement improvements based on feedback and lessons learned to enhance efficiency and reliability over time.

- Stagnation or complacency in maintenance practices can hinder operational efficiency, limit performance gains, and compromise compliance in the auto body repair industry.In essence, the bullet points in our maintenance guide serve as a roadmap for navigating the intricate cause-and-effect relationships inherent in the care of high-powered liquid-cooled resistance spot welders. By understanding the underlying principles driving each maintenance task, auto body repair professionals can proactively safeguard equipment integrity, optimize operational efficiency, provide proper spot weld penetration, and deliver superior results.

Maintaining a high-powered liquid-cooled or non-liquid-cooled resistance spot welder demands diligence, expertise, and attention to detail. By following these step-by-step maintenance guidelines and adopting a proactive approach to care, you can ensure optimal performance, extend the lifespan of your equipment, and deliver superior results in automotive welding applications. Remember, precision in maintenance translates to precision in repair work, setting the stage for excellence in auto body repair and restoration.

So What Do You Think?

Please Leave A Comment Below - We'd Love To Get Your Opinion.

Would you like more information about our Spot Welders and purchasing options?

FINANCE IT: Pro Line Systems provides low-rate financing for all their equipment.

You can fill out a simple no-obligation online application. Fill Out The Financing Application Here.

FYI: Hey, Curious about Giulio Valle, the Authoritative Author, and creator of this Blog and the