GYSPRESS 10T Aluminum Self Piercing Rivet Gun Workstation

Dent Pullers Rivet Guns

GYSPRESS Push Pull Self Piercing Rivet Workstation

The FUSION of Imagination, Technology, Engineering, And The Desire To Create An Outstanding Cutting Edge Self-Piercing Riveter Workstation Has Been Achieved by GYS International.

The Most Technically Advanced / Electronically Enhanced SPR Workstation Available For Modern Collision Repair Operations.

Starting At - $13,400

The GYSPRESS 10T Self Piercing Rivet Gun Workstation with Push-Pull Control advances SPR Riveting to a new level of performance.

The following features and performance characteristics combined with the user-friendliness of this aluminum and steel self-piercing riveter workstation are second to none.

- The 10T rivet gun workstation generates ten tons of easily adjustable precision force (+/-3.3%).

- Changing C-Arms is fast & easy.

- The included gun stand conveniently positions the 10T riveter in an upright position for easy change-out of C-Arms and dies.

- Two control buttons on the SPR gun: One for activating self-piercing rivet insertion & flow form rivets flattening. The 2nd button for opening the riveter or hole punch extraction.

The GYSPRESS 10T Push Pull Aluminum & Steel Self-Piercing Riveting Workstation.

The Self-Piercing Riveting Workstation Of The Future.

Provides comprehensive electronic guidance through the setup of the rivet gun and

electronic control of the riveting process exactly as the car manufacturer requires.

This cutting-edge SPR workstation provides all car manufacturers specific OEM-approved methods.

Just roll the Workstation to the next job and start riveting with all accessories conveniently available.

The cabinet also provides enclosed shelf storage for additional supplies and accessories.

You will agree that no other SPR riveting system compares to this state-of-the-art Workstation.

- *Optional accessories such as the award-winning Blind Rivet Adapter is available.

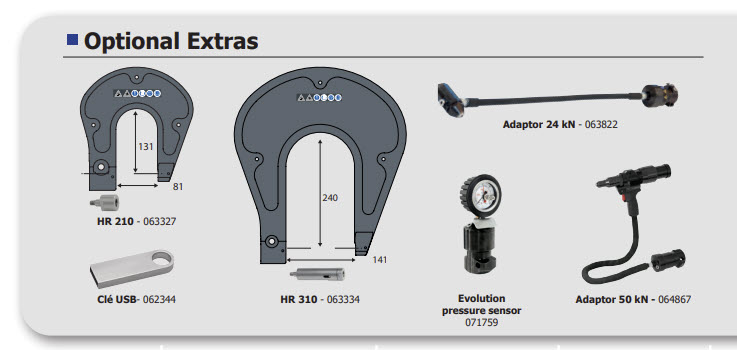

- *Optional HR210 and HR310 long-reach arms.

- The standard 10T Push-Pull die kit is included.

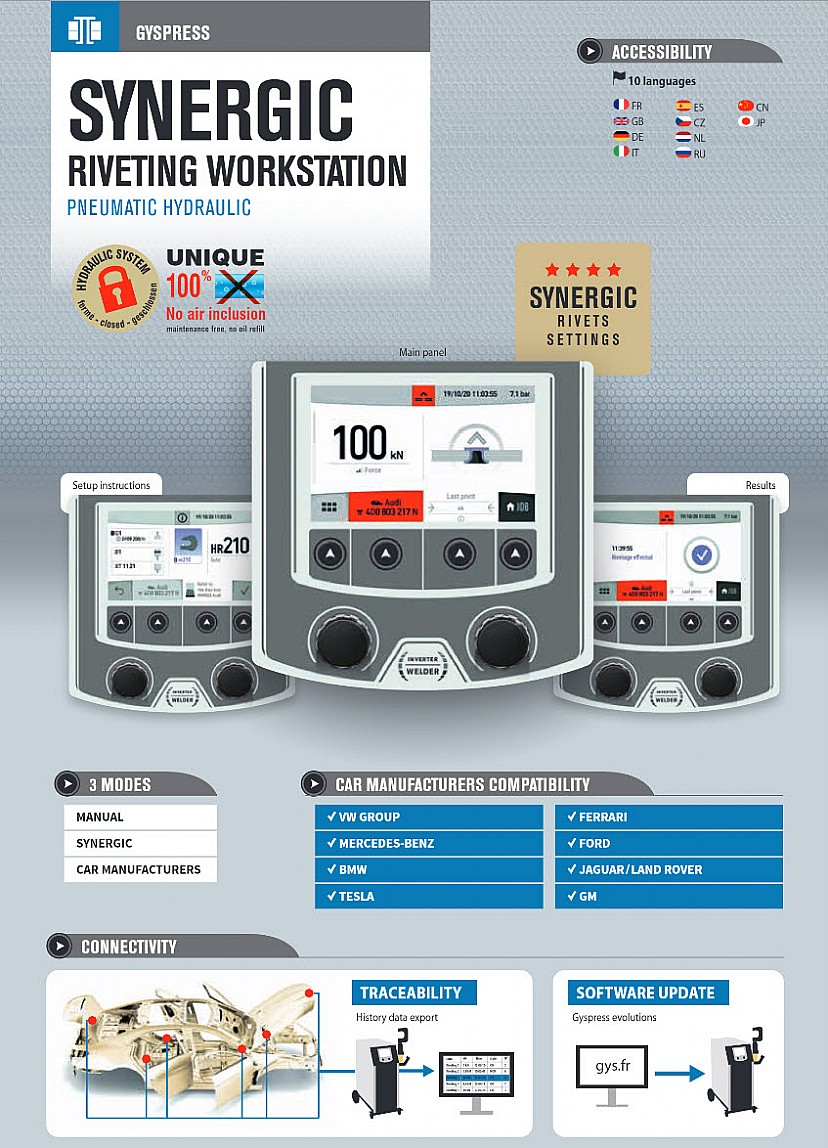

The user-friendly 5" Color display provides up-to-date vehicle data that guides the technician step by step through the proper setup of the riveter for the specific job. No guesswork saves time and a perfect setting of self-piercing or flow form rivets.

- Riveting information is saved to an SD memory card, providing the traceability of each installed rivet. This information can be printed showing all details for each rivet installed.

- This provides security for you and your business and shows proof of the professional quality of the repair that matches the car manufacturers' requirements.

Store all riveting data and system updates to SD card and USB drive when new updates are available. Repair verification printouts for all to see is a very powerful asset to your business.

SMART RIVETING:

- SYNERGIC mode: The on-screen interface guides the user to the dies to be used and the user to the dies to be used, as well as the required force, depending on the type of rivet being placed.

- Traceability: The machine can record riveting operations for completely accurate traceability.

- Playback recorded reports on a PC.

REGULATING THE SETTING FORCE:

- A built-in hydraulic pressure sensor enables the riveter to check that the required installation force has been achieved.

MULTI-BRAND COMPATIBILITY:

- Tesla, VW Group, Mercedes-Benz, BMW, Ferrari, Ford, Jaguar / Land Rover, General Motors, and more.

SOLID BUILD AND AND MOBILITY:

- Reinforced casing and maneuverable trolley with built-in shelved storage unit.

- Spacer on the front wheels for increased stability.

- Three integrated c-arm supports.

FYI: If you need a less elaborate riveting tool, check out our #1 selling Self Piercing Gun Options.