Spectratek UV Ultraviolet Curing Lamps

Paint Curing Lamps

Spectratek UVLED - Hand Held and large curing lamps, Cures UV Primer, Filler, Putty, and Topcoat.

AMH Canada - Spectratek Division

The developers of the first UV LED UltraViolet curing lamps. Providing extreme

high efficiency no heat curing - low power consumption - Impressive all digital microprocessor controlled operation with extremely short curing times

Call Us 305-793-9503

- Gas Powered Shock Provides Multiple Access To All Sides And Top Of the Vehicle

Running Cost Is Much Lower Than Conventional Methods

- The UVTEK 2000 / 3000 / 4000 UV lamps meet or exceed the highest international standards for performance and safety. They are designed and built in North America for use worldwide on all current ultraviolet light curable fillers, base coats (primers), top coats, and clear coatings on: • Metal (including aluminum) • Plastic • Wood • Concrete • Glass • Composites.

Spectratek UVTEK UV Paint Curing Lamps Offer Exceptional Performance

• Provide uniform curing over the widest areas

• Are faster than other curing methods/cures UV reactive coatings in seconds

• Generate no heat on the work surface • Utilize less energy

• Provide opportunities to reduce production costs

AMH Canada invests in extensive research and testing in conjunction with paint manufacturers to ensure the continued development of the highest quality products to meet industry needs today and in the future.

Versatile Models UVTEK UVLED 2000 / 4000

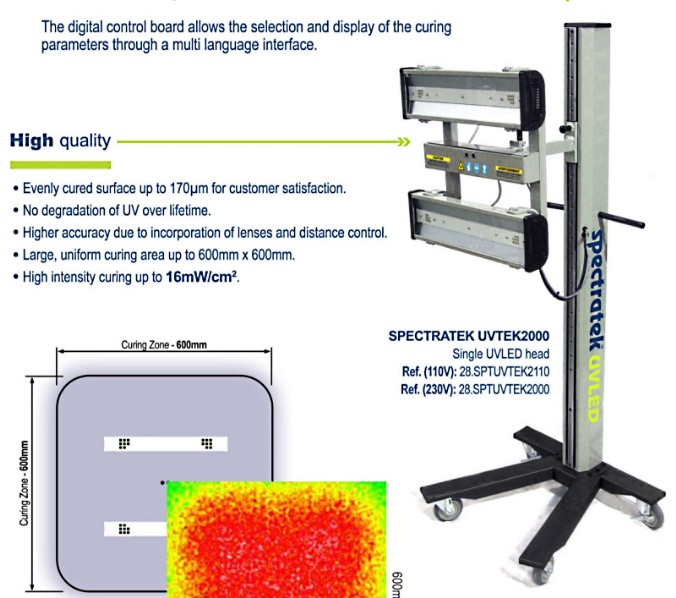

UVTEK 2000 UVLED - The Industry's Value Leader

- Even surface curing for user satisfaction

- Higher accuracy due to the implementation of lenses and distance control

- No degradation of UV over time

- Large uniform curing area of 600mm x 600mm

- High-intensity curing up to 16mW/cn2

- Filtered for safe UV-A radiance

Cure UV reactive primers, fillers, putty & clear coats with extreme speed.

What used to take hours to cure now takes a few minutes or less.

Precision Digital Control Panel

AMH Canada Ltd engineered the New UVLED UV curing lamp line with the most advanced LED technology.

Faster, safer, and more efficient than any other conventional UV Curing system for automotive repair and industrial finishes.

The Spectratek LED UV curing lamps are environmentally friendly with low energy consumption and are safe to use.

All harmful UVB and UVC Rays are filtered out, providing the user with a safe environment without the need for protective gear.

Paint Production Benefits

- Almost instant full cure with no heat

- Ready to sand, buff, and deliver in under 3 minutes

- Emits only UVA radiations (395nm) No more harmful UVB and UVC

- Manufactured with a unique passive thermal management system specially designed for high-power UV LED modules

No cooling fan is required - All the modules are equipped with a distance sensor and a digital control board

- A lifetime of more than 30,000 hours

- Each UV LED headlamp provides a uniform radiation

Average irradiance: 7.0mW/cm2

Maximum Irradiance 9.5mW/cm2

The Next Big Thing In UV Paint Curing, It's Here. Small and medium spot drying in record time is now possible

Click the Instacure UVLED Rechargeable Hand-Held Curing Lamp To Learn More

FYI: Latest Update: Dive into Our Blog Post About This Advanced Hand Held UV Curing Lamp

Check out the New SpectraPro NUVA UV curable filler & putty. In combination with our UVLED lamps it takes just seconds to cure UV reactive coatings. Imagine the time savings and shop output that equals high profits for you.

FYI: Interested in learning more about why the Spectratek Curing Lamps are highly recommended by all major automotive paint manufacturers? Check out our blog post here.