Auto Body Repair Equipment Essentials For 2024

Published by Giulio Valle in Body Shop Equipment · 24 February 2024

Tags: Auto, Body, Repair, Equipment, Essentials, For, 2024, backed, by, statistics

Tags: Auto, Body, Repair, Equipment, Essentials, For, 2024, backed, by, statistics

Auto Body Repair Equipment Essentials For 2024

Does your auto body repair facility meet the expectations of your customers and their insurers in 2024?

In the world of auto body repair, staying up-to-date with the latest tools and techniques is paramount. As we delve into the landscape of 2024, let's explore the essential equipment every modern auto body repair shop needs, backed by statistics and insights from industry experts.

FYI: Although your choices are many, to help you better understand the equipment categories in this blog post, we use examples of the auto body shop equipment we sell here at Pro Line Systems International Inc.

If you have any general or purchasing questions, please call Giulio Valle, President and Founder

for a free consultation 305-793-9503

Precision is key in auto body repair, and laser measuring systems have revolutionized how professionals assess damage and ensure repair accuracy.

These systems use laser technology to measure various points on a vehicle, providing comprehensive live data for realigning frames and panels. According to a survey conducted by Collision Repair Magazine, 78% of auto body repair shops reported an increase in efficiency after integrating laser measuring systems into their workflow. This technology not only saves time but also enhances the quality of repairs, ultimately leading to higher customer satisfaction rates.

Before and After Printouts are an invaluable resource. Check It Out Here

Spot welding is a common technique used in auto body repair to join metal panels together. Smart spot welders leverage advanced technology, such as automatic calibration, to achieve consistent and durable welds. In 2024, these welders have become essential for maintaining the structural integrity of modern vehicles, which increasingly rely on lightweight materials like aluminum and high-strength steel.

Stat: The automotive welding market size is expected to reach USD 9.30 billion by 2025, growing at a CAGR of 4.5% from 2019 to 2025.

Source: Grand View Research

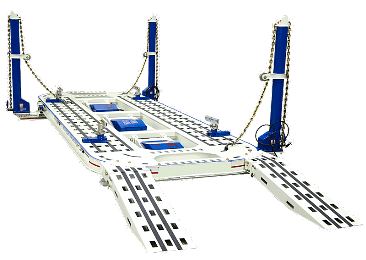

Advanced Frame Straightening Systems:

After a collision, a vehicle's frame can become misaligned, compromising its structural integrity and safety. Advanced frame straightening systems utilize hydraulic power and simultaneous multiple pulling with equalized pressure technology to restore the frame and body to its original specifications. In 2024, these systems have become more precise and efficient, reducing repair time while ensuring optimal results.

Have a look at the very popular Made In USA - American Freedom Multi Point Frame Pulling Machines Here.

Stat: The global collision repair market size was valued at USD 184.5 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 3.0% from 2020 to 2027.

Source: Grand View Research

Aluminum Repair Equipment:

With the increasing use of aluminum in vehicle manufacturing, auto body repair shops must equip themselves with specialized tools for working with this lightweight yet durable material. Aluminum dent pullers and self-piercing rivet guns are just a few examples of equipment necessary for repairing aluminum-bodied vehicles.

According to a report by IBISWorld, the demand for aluminum repair equipment has surged by 24% in the past two years, driven by the rising popularity of aluminum-intensive vehicles among consumers.

As automakers continue to incorporate aluminum into their designs for its performance and fuel efficiency benefits, the need for specialized repair equipment will only continue to grow.

Paintless Dent Repair (PDR) Tools: Paintless dent repair has gained popularity in recent years due to its cost-effectiveness and efficiency. PDR tools, such as dent pullers and metal rods, allow technicians to remove dents without the need for repainting, preserving the original finish of the vehicle.

Paintless Dent Repair (PDR) Tools: Paintless dent repair has gained popularity in recent years due to its cost-effectiveness and efficiency. PDR tools, such as dent pullers and metal rods, allow technicians to remove dents without the need for repainting, preserving the original finish of the vehicle. According to the Automotive Service Association (ASA), 63% of auto body repair shops now offer paintless dent repair services, citing its ability to attract customers and increase profitability. In 2024, investing in high-quality PDR tools is essential for any repair shop looking to stay competitive in the market.

Self Piercing Rivet Guns: GYSPRESS 10T and Push Pull Versions with Mega Ten Tons precision Force and 2 Year warranty

Self Piercing Rivet Guns: GYSPRESS 10T and Push Pull Versions with Mega Ten Tons precision Force and 2 Year warrantyThe new method of vehicle assembly and repair. This is another amazing tool auto body shops must adapt to.

Self-piercing rivets, also known as SPRs, have become increasingly popular in the auto body repair industry over the past few years. These innovative fasteners can join sheet metal together without drilling holes, which means they can be used to make precise repairs without compromising the integrity of the vehicle. Check out this bad boy here. Watch the Videos.

FYI: If you're new to using self-piercing rivets, here are a few tips to help you get started.

AIRFIX Draw Aligner Air Suction Dent Pulling Post:

Smart body shop owners are always on the lookout for new technology that can increase production through innovative technology.

The New AIRFIX Draw Aligner Air Suction Pulling post requires No anchor pots or chains to hold it in place. The specially engineered Air Venturi design draws the puller to the floor through powerful and quiet air suction.

You can use this amazing puller anywhere in the shop with no floor anchors needed. Check out this amazing puller right here.

Learn More about this game-changing puller here. Watch The Video.

In an era where sustainability is at the forefront of consumer consciousness, auto body repair shops are increasingly turning to eco-friendly paint systems to reduce their environmental footprint. Water-based paints, low-VOC (volatile organic compound) primers, and infrared curing technology are some examples of eco-friendly alternatives gaining traction in the industry. Now with the advancement of UVLED curing technology, auto body repairers can cure UV-reactive products in a few minutes rather than hours.

Stat: According to a survey conducted by BodyShop Business, 82% of consumers are willing to pay more for auto body repair services that use environmentally friendly practices and materials. By investing in eco-friendly paint systems, repair shops not only appeal to environmentally conscious customers but also contribute to a greener future for the automotive industry.

Here Is A Non-Essential Tool, But 'WOW" Why Does Everyone Want One?

Our Customers are in Disbelief at how this battery-operated Electro Power tool can generate 5 Tons of

versatile Push Pull Power. It's like a frame machine in your hand

Check it out and buy one, you won't be able to resist!

So There You Have It:

The world of auto body repair is constantly evolving, driven by advancements in technology and changing consumer preferences. In 2024, staying ahead of the curve means equipping your repair shop with the latest tools and equipment tailored to meet the demands of modern vehicles and discerning customers. From laser measuring systems to eco-friendly paint systems, each piece of equipment plays a vital role in ensuring efficient repairs and customer satisfaction. As we continue to embrace innovation and sustainability, the future of auto body repair looks brighter than ever.

*For more information about ordering or just need more product information

Contact: Giulio Valle, at Pro Line Systems International Inc. For A Great Deal!

FYI: Curious about Giulio Valle, the Authoritative Author, and creator of this Blog and the