CMO RV700 Approved Self Piercing Riveter

Published by Pro Line Systems in Informational · 11 August 2023

Tags: CMO, RV700, Self, Piercing, Riveter

Tags: CMO, RV700, Self, Piercing, Riveter

Product Spotlight:

The CMO RV700 Digital Self-Piercing Riveter

The RV700 Self-Piercing Riveter (SPR) is a recommended tool that has been approved by several OEM vehicle manufacturers for cold-joining aluminum and steel panels together and for precisely removing rivets.

Approved by: Ford, Jaguar JLR Program, Aston Martin, Land Rover Approvals.

FYI: After reading this article and are interested in purchasing this remarkable CMO RV700 Riveting System

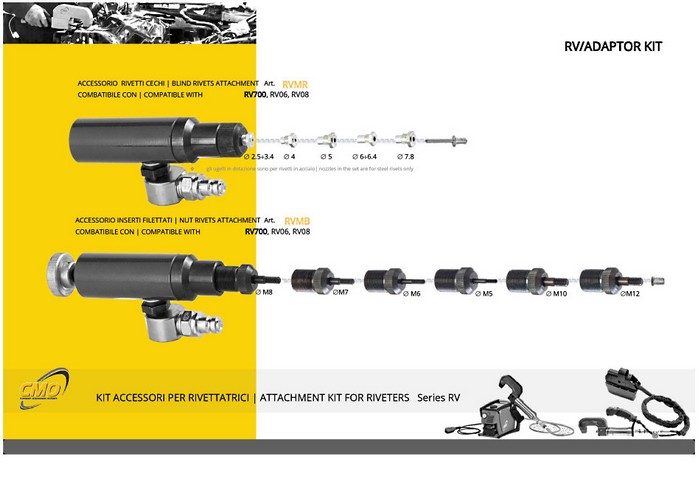

The cold-forming technique requires no heat and no pre-drilled holes. The CMO SPR Riveter is a reliable tool for riveting aluminum and/or steel panels with high dynamic strength. Additionally, several optional accessories can greatly enhance the machine’s capabilities to install different types of fasteners like Blind Rivets and Riv-Nuts (see RV/ADAPTOR ) and Hole Punching ( see RV22C).

Quick Note: You can see more details and other

This is one very versatile machine that can perform multiple tasks making the riveter

an even smarter investment to consider.

The RV700 Riveting System is a battery-operated, hydraulic riveting system that allows the operator to select or adjust the recommended force (kN level) and insertion speed with full digital control. This is important to be able to make fine adjustments depending on the material being riveted to increase accuracy and prevent panel distortion to the panels.

FYI: Users should always follow the OEM recommendations. All these functions are digitally controlled and able to be fine-tuned for exceptional performance automakers demand.

The RV700 Rivet Gun Is A Very Smart Riveting Solution, And Smart Investment.

Fully Electronically Controlled With Benefits Beyond Compare - Read On...

The micro-control system built into the l-pump has the capability of recording, and allowing the download of riveting data, creating specific programs, and generating riveting job reports. The failsafe feature prevents the operator from riveting if there is not enough power left in the battery, meaning the unit cannot complete the riveting cycle, and prevents a failing rivet insertion. It automatically protects your shop against anything other than a qualified rivet bond. You have the advantage of printing out a rivet report showing proof of compliance.

On the graphical digital display of the machine, it is possible to check out real-time information about the pump, setup, and actual installation force, select pressure, and store custom riveting programs. The instant onscreen graph is capable of reporting whether the rivet has achieved the required pressure during installation.

The system has a lighted regulatory system and diagnoses when there is a fault with the machine and or if service is required. The I-pump device is equipped with a USB port for downloading recorded riveting data for producing documentation for making a printout and for firmware upgrades.

The HMI control has an Integrated intelligent electronic module with a large LCD display and additional LED indicators that provide rapid user information & status of the machine.

The progress of compression can be displayed on the screen that shows: pressure, operating time, pressure, program #, battery power, and riveting force. The micro-controller control is very simple to use, selection steps, different phases, and program selection are progressed by using the l-drive knob dial.

All the data is saved into the PCB memory on the unit and can be read and downloaded by connecting the mini USB cable connector that is supplied with the machine. The com port is also used to perform Firmware changes, and factory settings/upgrades.

The Tool-Software for the RV700 CMO riveter is a license-free software that comes with the machine. The riveter's Plug & Play auto recognition enables the PC to receive and transmit data, generate job reports, and be of further support. At last, the traceability software can incorporate into the reports additional repair details like vehicle type, registration plate, name of the customer, and a short description of the job.

This program has a built-in calendar that registers the date and clock time of each operation the riveter performs with the corresponding values: Tool cycle data Counter | Date/time | Total running time | Target level Max level I Chip Temperature I Error & Waring message.

A Durable and Versatile Riveter Tool with Enhanced Safety Features

The pump body and all components of the riveter control case are carefully crafted from extensively tested high-resistance materials. The primary focus of the design is on creating a lightweight, compact, and robust structure.

Engineers at CMO have dedicated efforts to ensure the riveter's optimal performance in a wide range of working conditions, including temperatures ranging from -20°C to +50°C. To achieve this, they have opted for a casing made entirely of insulating, shock-resistant polyamide material, strengthened further with an additional layer of fiberglass.

Could this be the most advanced Micro-Processor driven riveter on the planet?

Leave Your Comment

Exclusive Features:

1. Material Selection: Build Quality

• The riveter's casing is constructed entirely from insulating, shock-resistant polyamide material.

• An extra layer of fiberglass reinforces the polyamide material, adding to its durability.

2. Versatility and Adaptability:

• The riveter tool boasts advanced technology that allows for easy adaptation with various attachments suitable for different applications.

• It is equipped with an electro-hydraulic pump, pneumatically driven, with a pressure ratio of 1:100.

• The hydraulic maximum output pressure achieved through this setup is 700 bar (70 MPa).

3. Automatic Pressure Regulation:

• The pump is designed with an automatic stop feature, ensuring it halts once the preset final pressure is reached.

• This automatic pressure regulation helps maintain a consistent pressure level for dependable performance.

4. Rapid Advancement Technology:

• A special double piston technology enables rapid advancement with low-pressure and slower high-pressure advancement.

• At approximately 90 bar (9 MPa), the conversion from low to high pressure occurs automatically.

5. Reverse Capacity:

• The riveter unit is engineered with excellent reverse capacity, enhancing efficiency and promoting faster working cycles.

6. Hydraulic Hose Package:

• The electro-hydraulic pump connects to the hydraulic hose package through a high-pressure hose.

• To ensure a leak-free connection, a quick-release hydraulic coupling conforming to the CEJN S115 standard is employed.

7. Ergonomic Remote Actuator Control:

• The remote actuator control incorporates easy-to-use buttons for ON, Forward, and Reverse functions, streamlining operation.

• An LED light is integrated into the control, providing real-time status diagnosis while the riveter is in operation.

• For user convenience, the handset is equipped with a fastening clip and integrated magnetic support, facilitating easy storage during stand-by.

Final Evaluation,

This extremely advanced SPR riveting tool developed by CMO stands as a testament to their dedication to quality, adaptability, and safety. Using high-resistance materials and cutting-edge technology ensures a durable and reliable tool for various work conditions. The ability to print out a riveting report, documenting each customer repair is phenomenal to your shop's professionalism and liability security.

The automatic pressure regulation and rapid advancement technology further enhance the efficiency and precision of the riveter's performance. Additionally, the ergonomic remote actuator control offers user-friendly features, including real-time status diagnosis and storage options. With its exceptional attributes, this SPR riveting tool is destined to excel in diverse industries, earning the trust of professionals worldwide.

FINANCE IT: Pro Line Systems provides low-rate financing for all their equipment.

You can fill out a simple no-obligation online application. Here

For more information about ordering or if you need more general information

Contact: Giulio Valle, at Pro Line Systems International Inc. For A Great Deal!

FYI: Hey, Curious about Giulio Valle, the Authoritative Author, and creator of this Blog and the