Auto Body Dent Puller - Capacitive vs Drawn Arc - A Special Report

Published by Pro Line Systems in Informational · Thursday 14 Sep 2023

Tags: Aluminum, Dent, Puller, Capacitive, Discharge, Machine, vs, Drawn, Arc

Tags: Aluminum, Dent, Puller, Capacitive, Discharge, Machine, vs, Drawn, Arc

Our ultimate showdown between two powerful auto body dent puller techniques

Capacitive vs Drawn Arc! Dive into our special report and discover who is the Ultimate Winner.

Our ultimate showdown between two powerful auto body dent puller techniques

Capacitive vs Drawn Arc! Dive into our special report and discover who is the Ultimate Winner.

So What Is The Best Aluminum Dent Puller For You:

Call: For Pricing And Availability - Pro Line Systems International Inc.

The selection between Capacitive Discharge and Drawn Arc welding techniques for particular types of aluminum compositions for auto body dent removal, primarily depends on the properties of the material and the specific welding process needs. Each method has unique benefits and may be more suitable for certain aluminum compositions for various reasons:

FYI: It is our experience that Drawn Arc aluminum dent pullers are the winning technology and provide exceptional performance for Dent Removal with best return on investment for many reasons. Read on and learn why you should check this report before making a purchasing decision.

Capacitive Discharge Dent Pullers: Advantages.

Swift Energy Transfer:

Capacitive discharge welding quickly delivers a high-energy pulse, typically within milliseconds. This rapid energy transfer is advantageous for thinner aluminum compositions as it minimizes heat input, reducing the risk of heat-induced distortion or warping.

Limited Heat-Affected Zone (HAZ): The short-duration energy pulse restricts the size of the heat-affected zone, which is advantageous for aluminum alloys sensitive to heat. It helps maintain the material's mechanical properties and decreases the likelihood of post-welding issues.

Appropriate for: Thin Aluminum Sheets:

Capacitive discharge welding is especially well-suited for Thin Aluminum sheets commonly employed in automotive bodies and panels.

Heat-Sensitive Alloys:

Aluminum alloys prone to heat-related problems, such as those in the 5xxx series, can benefit from capacitive discharge welding due to its lower heat input.

FYI: One frustration of the capacitive discharge machines is that it may not be as effective with all sizes of pulling studs and different composites & thickness of aluminum and break away from the panel during a pull. The Drawn Arc machines are much more effective with this issue due to the micro-processor circuitry that enable infinite adjustments.

The Capacitive Discharge machines are cheaper than Drawn Arc dent pullers. But are they really cheaper? Maybe not / Read on to learn why,

____________________________________

Drawn Arc technology: Does So Much More.

Continuous Arc: "Drawn Arc" welding provides a continuous welding arc, making it suitable for thicker and thinner aluminum compositions that require a sustained heat source to melt and fuse the material.

As a Plus, most Drawn Arc Dent Pullers can also be used for steel dent repair. As an example, our machines by

GYS - Drawn Arc 200 / 400 Series. > Check out these machines on our Pro Line Systems website.

As in all things, there are Pro's & Con's to everything.

• Explore the benefits of using a capacitive auto body dent puller technique

• Uncover the advantages of utilizing a drawn arc auto body dent puller method

• Compare and contrast the pros and cons of capacitive vs drawn arc dent pullers.

Read On And Become An Expert.

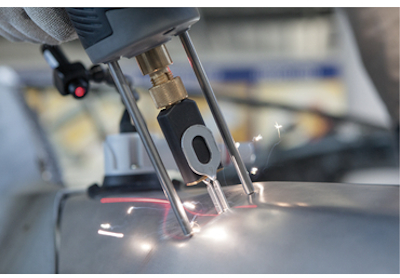

and see the amazing control it offers the technician.

A very professional introduction to this remarkable industry approved machine.

Enhanced Control:

Drawn Arc dent pulling machines offer superior control over the welding process, allowing for precise penetration and accurate placement of the weld tabs. This level of control can be crucial for applications where weld quality and integrity are of utmost importance. This is shown in our Video above. Watch it!

Appropriate for:

Thick And Thin Aluminum Components: Drawn arc welding is frequently employed for thicker aluminum components, such as structural elements in construction or heavy machinery and auto body repairs..

Precision Stud & Pull Ring Welds:

Applications necessitating precise control over the weld, such as aerospace components, auto bodies which employ many different compositions of aluminum with many different thicknecess may prefer drawn arc welding. for it's ability to fine tune the settings for superior performance.

Aluminum's Role in the Automotive Sector: A Concise Overview

Aluminum has a rich history in the automotive sector, dating back to the early 20th century. Initially used in vehicle bodies, it faced limitations due to high costs and limited production capabilities. However, over the years, aluminum has evolved to become a crucial material in automotive manufacturing.

Key Milestones Of Aluminum In Carmaking:

Early Use: Aluminum was first used in vehicle bodies due to its malleability and ease of shaping.

1961 Breakthrough:

Aluminum alloys gained traction in 1961 when British Land Rover successfully produced V-8 engine blocks from aluminum, showcasing its potential.

Expanding Applications:

Aluminum's versatility led to its use in critical automotive components, including wheels, transmission castings, cylinder heads, and suspension joints.

Ongoing Preference:

Aluminum remains a preferred material for automobile bodies, with technological advancements enabling its use in powertrains and structural components.

Diverse Aluminum Alloys in Automotive Applications:

Modern automobiles consist of numerous components that can be efficiently made from aluminum. Aluminum's versatility arises from its ability to form various alloys, each with unique chemical and mechanical properties. Some primary aluminum alloys used in the automotive industry include: 1100-2024-3003-3004-3105-4032-5005-5052-5083-5182-5251-5754-6016-6061-6181-7003-7046

These alloys offer a range of characteristics suited to specific automotive applications.

Variety of Aluminum Formats:

In addition to diverse alloys, aluminum is available in various formats and conditions, providing flexibility in automotive manufacturing. These formats include aluminum sheet, aluminum plate, aluminum bar, and aluminum tube, further contributing to aluminum's popularity in the automotive industry.

In summary, the decision between capacitive discharge and drawn arc welding for specific aluminum compositions relies on the material's thickness, sensitivity to heat, and the required precision of the weld. Capacitive discharge welding is favored for thin aluminum sheets and heat-sensitive alloys due to its swift energy transfer and limited heat-affected zone.

Drawn Arc welding is better suited for "thicker or thinner" aluminum components and applications demanding meticulous control over the welding process. Careful selection ensures the desired weld quality and minimizes the risk of material-related problems.

So Why Have We Declared Drawn Arc Technology As The Winner?

From our perspective and real world experience from our customers, if you want a more professional system that will provide you with the ability to address many more diverse types of aluminum, then the Drawn Arc technology is clearly the Victor and the way to go in 2023 and beyond.

So What Do You Think?

Please Leave A Comment Below - We'd Love To Get Your Opinion.

Would you like more information about these dent pullers and purchasing options?

Please Call: 305-793-9503

FINANCE IT: Pro Line Systems provides low-rate financing for all their equipment.

FYI: Hey, Curious about Giulio Valle, the Authoritative Author, and creator of this Blog and the

_______________________________________________