Laser Measuring Systems For Auto Body Repair - What Are They?

Published by Pro Line Systems in Informational · Friday 21 Oct 2022

Tags: Auto, Body, Repair, Using, Laser, Measuring, Systems

Tags: Auto, Body, Repair, Using, Laser, Measuring, Systems

Laser Measuring Systems, What Are They?

Choosing to settle for subpar repair accuracy when you require unibody or frame damage repair is out of the question. In the past, measuring a car or truck may have been sufficient even if it wasn't strictly accurate. This is no longer the case now that Laser Measuring Systems are used.

Repairs require high accuracy.

A vehicle's unibody or frame damage cannot be accurately repaired without an accurate measuring system, given today's low tolerances. In some instances, tolerance has been reduced to 3 millimeters, resulting in virtually impossible accuracy with old methods. To be repaired, a vehicle must first be accurately measured and blueprinted to be able to form a repair plan. This is sometimes referred to as Mapping.

Live Reading Target Polar Scanner

Video Demonstration Of Laser Measuring System by Mark Worman

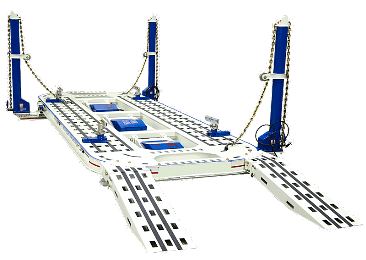

A Laser Measurement System Overview

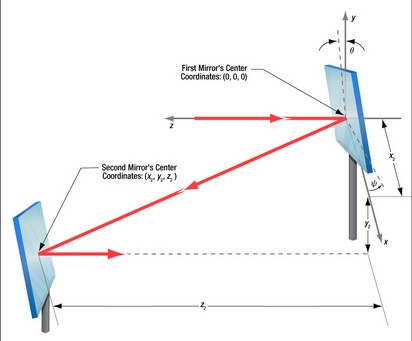

Targets are installed at control points throughout the vehicle using our laser measuring system. After the targets are installed, a beam of laser light is sent to each target, sending precise measurements to the computer software providing XYZ (length-width-height) readings displayed on the monitor. The technician now knows the misalignment in millimeters and which direction he needs to reverse the damage.

Once set up, the measuring magic begins and provides the technician with live measurements that are continually updated during the entire pulling process at the speed of light.

Appropriate Diagnosis

Having the correct diagnosis before beginning repairs ensures that the repairs are done correctly and do not deviate in size and factory specifications.

The system produces highly accurate measurements that are exact to the millimeter.

It is critical for the technician to properly place the targets to ensure that the system generates the correct measurements. The system will indicate if a target is placed in the wrong control point and advise the technician to correct the error. The big gain here is that there is no chance of making any mistakes.

Reduce Repair Time

Laser Measuring Systems are a fantastic way to reduce repair times. Using the old methods to measure would have been far less efficient. With the Laser Measuring System, we can diagnose and repair the vehicle to its pre-damage condition just as accurately as before.

The intricacy of laser measurement systems is just one example of the level of sophistication that we must use to diagnose and repair the modern vehicle frame and body structure.

A shop's liability, reputation, and customer safety are critically important, there is no room to compromise on this responsibility of insuring the vehicle is 100% repaired to industry standards before the vehicle hits the road.

You might also like: How to choose the best electronic laser measuring system for your shop.

Are you looking for an Auto Body Repair Equipment Supplier with an excellent reputation, products, and pricing? Click here to get to know Pro Line Systems International.

Please contact us if you have any questions regarding our publications or products.

Our support is cheerfully given.