GYS Auto Body Equipment - The History Behind Their Huge Success

Published by Pro Line Systems in Informational · 22 February 2023

Tags: GYS, Auto, Body, Equipment, |, GYS, Tools, |, Spot, Welders, |, Pro, Line, Systems, International

Tags: GYS, Auto, Body, Equipment, |, GYS, Tools, |, Spot, Welders, |, Pro, Line, Systems, International

GYS Manufacturing Facility - France

Thanks to an aggressive investment policy, GYS, a welding equipment manufacturer, has developed exceptional R&D capabilities, making it the largest of its kind in Europe Established in 1964.

Here is a bit of GYS International's company history and how it has achieved its highly recommended

status in the worldwide industry.

GYS has established a definitive trait of relying solely on its capabilities to climb to the highest echelons of the welding industry. Since its renaissance began in 1997, the French family-owned group has demonstrated a strong commitment to engineering and manufacturing welding, automotive body repair, and battery service equipment. With a firm focus on constant investment in R&D and continuous improvement of manufacturing processes, GYS has achieved remarkable organic growth year on year. By making prudent financial decisions, the company has proudly claimed the position of Europe's largest manufacturer of inverter welding machines.

According to GYS UK's Managing Director, Neil Pulsford, fast-growing companies often face a lag in perception compared to reality. This is true for GYS, and the company works hard to communicate properly to inform customers of its present capability. It is common for people to be genuinely surprised at the scale of GYS's operations nowadays.

A Journey of GYS History

Neil proceeds to take us on a journey through GYS's history, intertwining it with an account of the revolutionary technological developments in the welding industry in the last two decades. GYS's timeline can be divided into two periods, according to him. The first period began in 1964 when Guy Yves Stephany founded the company in response to the change of voltage from 115 V to 230 V initiated by the state-owned Electricity of France company. Stephany's idea was to manufacture transformers on behalf of Electricity of France for households in the western part of the country.

During the 1970s, GYS expanded its product range with car battery chargers and welding machines, and the company's success continued to flourish in the following years. However, the latter part of the 1990s brought a decline that left GYS on the brink of bankruptcy. During this time, the manufacturer's current owners, D-Nicolas and Bruno Bouygues (father and son) stepped in and initiated a revolution that transformed GYS into what it is today.

Neil emphasizes that being a family-owned company has enabled GYS to deliver a true long-term strategy without influence from external investors.

The owners' steadfast belief in the need to invest heavily in R&D has been a cornerstone of the company, fueling double-digit annual growth for some 20 years now. GYS is a learning organization, constantly expanding its knowledge and mastering the ever-changing technology in the latest, most complex welding equipment they manufacture. The company's culture of continuous improvement has helped them innovate and develop products that meet the changing needs of its customers. This has allowed GYS to stay ahead of the competition and remain a leader in the welding and battery service equipment industry. As a result, GYS is well-positioned to face future challenges and continue to grow and thrive.

Looking back at the end of the 20th century, the core of a welding machine was a transformer power supply, which was a very basic technology. However, an incredible technology shift has occurred, turning modern welding machines into extremely complex electronic devices. This change has revolutionized the welding industry, introducing new technologies to improve the quality, efficiency, and safety of welding. Today's welding machines have sophisticated features such as digital controls, programmable settings, and automated smart welder functions, making them more efficient and easier to use. Adopting these new technologies has allowed welding companies to increase productivity, reduce costs, and improve the quality of their work. As technology continues to evolve, it is expected that further advancements will be made, leading to even greater improvements in the welding industry.

Related Products > Browse Our Mig Welders and Spot Welders

The Shift Toward's Inverter Welding Machines

Neil explains that the term used in the industry is "inverter welding machine," which refers to the move toward an electronic power supply. This shift towards electronics coincided with when Nicolas and Bruno acquired the business, and they were eager to embark on a journey of continuous investment in this area. GYS maintains a large R&D team whose work has helped the company establish a product range of over 70 different machines. This is a significant transformation from where the company was in 1997. With its commitment to R&D, GYS has stayed at the forefront of technology in the welding industry, introducing new products and features that set new industry standards. The company's innovation and continuous improvement culture have allowed it to adapt to changing market conditions and customer needs, positioning it as a leader in the welding and battery service equipment industry.

FYI

These are two very popular & powerful industry-approved GYS Inverter Spot Welders.

Click the photos to learn more / Watch the Videos on the pages

Staying on Top of Developments

Keeping up with the latest advancements in welding technology and efficiently communicating the capabilities of new models is a major challenge both manufacturers and users face. The rapid modernization of the industry has led to the generation of new knowledge, which calls for manufacturers to exert additional effort in transferring this intelligence down the supply chain. This requires investment in training programs, user manuals, and other resources that provide clear and concise instructions on operating the equipment, particularly given the increasing complexity of modern welding machines. Users must also be willing to invest time and effort to learn about the latest developments in the industry.

In markets where technology is rapidly advancing, it can be challenging for both end-users and local distributors to keep up with the latest equipment and its capabilities. As a result, manufacturers are responsible for informing customers about their products. This requires the right approach and a commitment to investing in local markets.

GYS's strategy is to make significant investments in growing its service capabilities by providing full support to its key local markets, including the UK, Germany, France, and Italy. They have established strong subsidiaries in these regions, employing highly skilled industry experts to provide their customers with the highest level of service and support. By investing in local markets and establishing a strong service presence, GYS can ensure that its customers are informed about their products and receive the highest level of service.

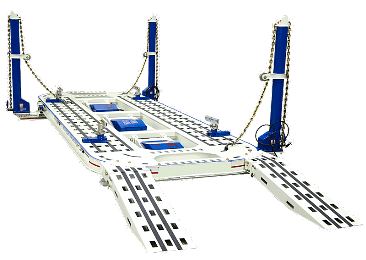

Have a look at their Advanced Steel and Aluminum dent pullers.

GYS's welding equipment range represents most of the group's turnover, accounting for more than half of its revenue. The remaining share is divided between the company's car body welding range (25%) and battery charger and maintenance products (20%). Despite the difference in product focus, there is a significant overlap in the requirements that GYS needs to meet when manufacturing these three product families.

For GYS's UK Managing Director, Neil, branching out into other battery environments presents growth opportunities for the otherwise automotive-oriented division. With the growing application of battery technology, especially lithium, for off-grid storage, there is a potential for significant growth in this market. GYS can capitalize on this growing trend by expanding its battery product offerings and further diversifying its product portfolio.

An Important Milestone

GYS products are now found in many car manufacturers' approved equipment programs like Tesla, GM, Ford, and many more. They have found GYS Equipment to be excellent machines for their certified repair programs.

Two such Spot Welders are the PTI-S7 and the PTI.G Genius Smart Welders featured here.

Another area that GYS International has excelled in is the Self Piercing Rivet Gun market. More auto manufacturers are turning to SPR riveting in the assembly of car and truck bodies. The best-selling Self Piercing Rivet Gun on the market is the (10 Ton) GYSPRESS 10T - Learn More Here GYSPRESS 10T The #1 Selling SPR riveter.

Their new GYSPRESS 10T PP Digital Control Workstation is an amazing advancement in SPR technology. Learn more about it and Watch the Video here. GYSPRESS 10T PP Workstation. Be Amazed...

Related Products

GYS has achieved an important milestone in its welding capabilities. It is now a full-range welding supplier, having completed its industrial welding catalog, which can serve every market segment. This achievement has fueled GYS's growth, with the organization seeing a 40% growth in its UK activities since the beginning of 2019 and double-digit growth in its other major markets.

Looking to the future, Neil outlines GYS's strategy: to raise brand awareness and let the welding industry know about its proposition. While the company is growing at an excellent rate, there are still markets where its share is modest, and GYS is seeking to increase its share in these areas by improving communication with the industry. The company is confident that its proven successful model will also bring further growth in these areas.

Pro Line Systems is a reputable distribution arm of GYS auto body repair equipment. We are distributors of high-quality auto body repair equipment brands in all categories since "2002".

Visit our website and explore our special offerings here. https:prolinesystems.net

Contact us with any questions you may have. Our free consultation is cheerfully given. 305-793-9503