Compuspot 1000 Industrial Spot Welder

WELDING & Cutting

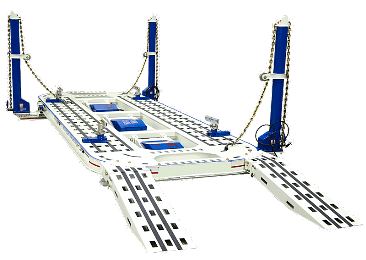

The CompuSpot 1000 Industrial spot welder is the perfect overhead Industrial spot welding system

for sheet metal product manufacturing and Car Maker Vehicle-In-White production applications.

High volume autobody repair facilities benefit greatly by creating valuable uncluttered floor space

and quick access to the weld clamp in any position. Overhead Suspension is Available.

The AMH 1000 Industrial Overhead Network Spot Welder

With Advanced Spot Welding Liquid Cooled Clamp for Industrial Applications

- The solution for spot welding and the demands of mass production

in the sheet metal and body-in-white industry.

- Medium frequency DC transformer.

- IGBT, transformer and electrode arms are water cooled to the electrode tips offering the industry's highest cycle time benefits.

- Ensured weld quality: adaptive closed loop control systems effectively process highly-variegated material combinations (Dynamic Resistance).

- 6 programmable user levels for demanding applications.

- Easy manipulation with an arch.

- Emergency stop button.

- A suspended cabinet allows the control of the welder clamp.

- Available with a large variety of electrode arms according to all automobile requirement standards.

CompuSpot 1000 SpecificationClamping force: 1,150daN at 8 bar (2,540lbf at 115PSI)Power supply requirements:380/415V with 32A D Curve protectionMain frequency: 50-60HzMaximum welding current: 15,000A.Suspended Cabinet SpecificationsMain voltage: 400-500V, 3-PhaseMain frequency: 50-60HzDimensions (WxHxD): 575x 565x 250mm (23"x 22"x 10")Weight: 39kg (86lbs)*Specifications are subjet to change without noticeAdvantages of the Medium Frequency DC Transformer:

There are many advantages in the use of the medium frequency DC transformer for

body-in-white assembly:

Suitable for welding aluminium, stainless steel and coated sheets, three sheet welds and thin sheets of metal;

Reduces the formation of welding splashes;

Short welding times as a result of condensed output;

Low connection and energy costs, because of lower connection requirements and systematic mains loading, along with an optimal power factor;

MF transformer are up to 40% lighter than AC mains frequency (50Hz) transformer;

Better Weld quality.

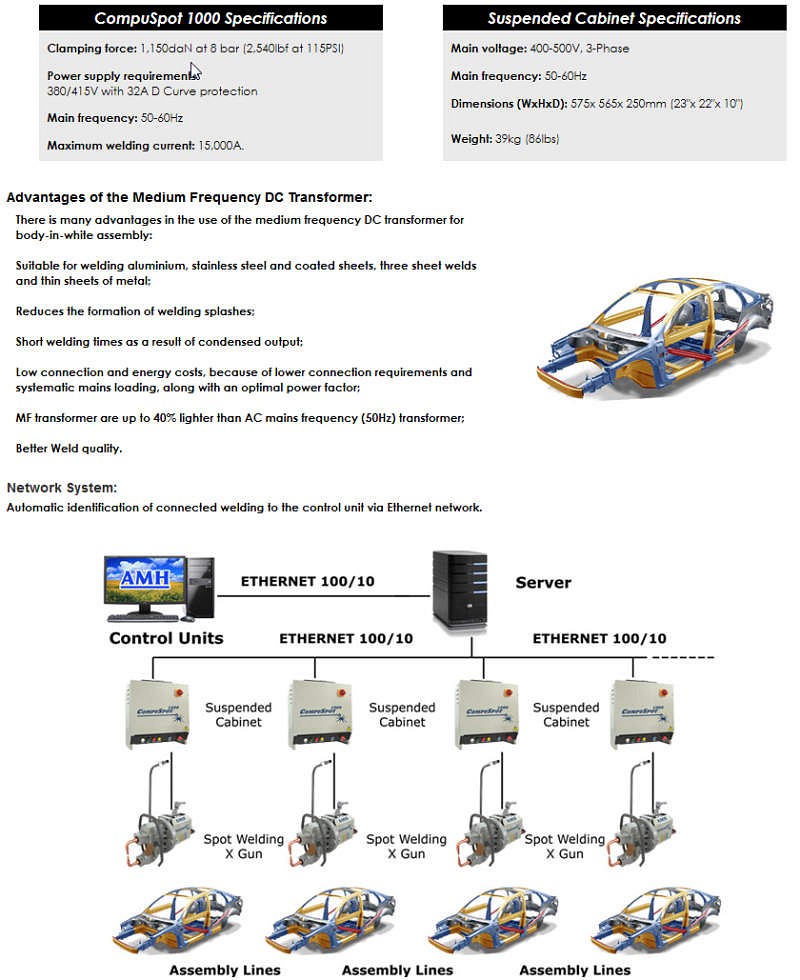

Network Spot Welder System:

Automatic identification of connected welding to the control unit via Ethernet network.

FYI Our engineers are available to provide a custom overhead configuration and ROI report for any industrial or auto body repair operation. Any industry needing a powerful and effective welding platform will be able to achieve a tremendous boost in time savings, enhanced capabilities and ultimate production levels.

We are Authorized AMH Canada Distributors: for Spectratek, Spectratherm, Compuspot, Ultramig, Blue Boy Benders, AlumAtech Aluminum Repair Station - CSA & CE Approvals - CSA CE & CCC Approvals.FREE Expert Consultation.

Call: Pro Line Systems International Inc. 305-793-9503

Giulio Valle