Dent Pullers For Aluminum And Steel Car Bodies

Published by Pro Line Systems in Informational · 4 March 2023

Tags: Dent, Puller, Machine, |, Professional, Dent, Pullers, For, Aluminum, Cars, and, Truck, Repairs, |, Pro, Line, Systems

Tags: Dent, Puller, Machine, |, Professional, Dent, Pullers, For, Aluminum, Cars, and, Truck, Repairs, |, Pro, Line, Systems

If you're in the auto body repair industry, chances are you've heard of a dent puller. But what exactly is a dent puller, and how does it play a role in an auto body shop? In this essay, we'll dive into the details and explain everything you need to know about auto-body dent pullers.

What is a Dent Puller?

A dent puller is used in auto body repair to remove dents and dings from a vehicle's body. Dent pullers come in various shapes and sizes, typically consisting of either a basic suction cup, a metal rod, or a pulling mechanism. The suction method is suited for pulling lighter dents. By attaching the suction cup to the dented area and using the metal rod to apply reverse force, the dent puller can slowly and carefully remove most of the dent.

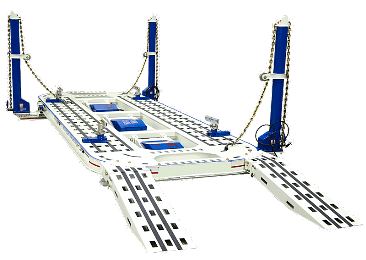

Shown is the Compuspot 180AL Aluminum dent puller.

Heavy damage will need the use of a more sophisticated electrically operated dent puller that can electrically attach pulling tabs, studs, and pins that will attach to tools like slide hammers and multiple pulling hooks or otherwise known as Bear Claws to a pulling bridge. This electrically operated dent-pulling machine can do a great job of straightening panels that have damage, especially to creases that require direct pulling tabs and extra pulling force to effectively pull the dent without detaching from the metal.

Different Things to Consider

When choosing a heavy-duty car body dent puller, it's important to consider the size and type of dents that you will be working on, as well as the materials that the vehicle is made of. Some heavy-duty dent pullers are designed specifically for aluminum or steel vehicles, and some will do both, so it's important to choose a dent puller that is compatible with the type of vehicles that you will be working on. Different technologies are used in professional electric-powered dent pullers. Capacitive Discharge and Drawn Arc operation.

Do you need a basic dent repair system or a complete workstation? The GYS dent-pulling machine and workstations are available at Pro Line Systems International. Check out their dent repair workstations here.

The Drawn Arc technology will provide many more options and settings to repair aluminum dents which require adaptability to the various compositions of aluminum. Drawn Arc Technology dent pullers are more expensive to manufacture and have a bit more of a learning curve to operate. It is worth the extra expense and training if you do lots of different vehicles made of aluminum.

Drawn Arc Technology, Dent Puller by GYS

The Role of a Dent Puller in an Auto Body Shop

In an auto body shop, a dent puller is essential for removing dents and dings from vehicles. Using a dent puller, technicians can repair a vehicle's body without having to sand down the damaged area and apply new paint, "PDR" (Painless Dent Removal) saves time and money. Additionally, by removing dents in a gentle and controlled manner, PDR dent removal applies outward pressure from behind the dent to help minimize the risk of damaging the vehicle's paint or causing additional damage to the body.

It's also important to consider the level of experience and skill of the technicians who will be using the dent puller. If you have experienced technicians, then a more complex and heavy-duty dent puller may be a good choice, as it will provide greater precision and control. On the other hand, if you have technicians with less experience, then it may be better to choose a simpler, more user-friendly dent puller that will be easier to operate and less likely to cause additional damage to the vehicle.

Additionally, you should consider the cost of the dent puller, as well as any additional expenses such as power sources, or replacement parts. Some heavy-duty dent pullers are quite expensive, and it's important to make sure that the cost is justified by the level of use and the types of dents that you will be working on.

Finally, you should consider the warranty and customer support provided by the manufacturer of the dent puller. A good warranty will ensure that you can get any repairs or replacement parts and consumables done quickly and easily, which can be especially important if you are using the dent puller daily. Additionally, good customer support will ensure that you have access to information and assistance when you need it, which can be invaluable in helping you keep your dent puller running smoothly and effectively.

Using a Dent Puller Safely

When using a dent puller, it's important to follow the manufacturer's instructions and use the tool correctly to minimize the risk of damage to the vehicle or injury to the technician. Here are some general tips for using a dent puller safely:

- Wear safety glasses

- Make sure you have a clear view of the dent and the surrounding area.

- Attach the pulling method at the center of the dent and make sure it's securely attached.

- Slowly and carefully apply pressure with the puller until the dent eases out.

- Stop pulling if you feel resistance, as this could indicate that the dent puller is damaging the vehicle's body.

- Use caution when removing the dent puller, as it may contain sharp edges.

Providing top Quality Repairs

A dent puller is an essential tool for auto body repair shops. The proper dent puller can make a significant difference in the speed, accuracy, and quality of repairs, which is why it's important to choose the right one for your needs. When selecting a dent puller, it's important to consider factors such as the size and type of dents you will be working on, the materials of the vehicle, the level of experience and skill of your technicians, the cost of the puller and any additional expenses, as well as the warranty and customer support provided by the manufacturer.

By considering these factors, you can ensure that you are choosing a dent puller that will help you provide the best possible repairs for your customers. Ultimately, investing in the proper dent puller can help you to save time, money, and resources, while providing the high-quality repairs that your customers expect and deserve.

Remember, when it comes to working on Aluminum and Steel panels it is imperative to keep tools separate and never mix using tools for steel on aluminum and tools for aluminum on steel. Something called Galvanic Corrosion will develop and your customer will be knocking on your door when he sees a deterioration in his paint etc. and there goes an expensive do-over and a bad experience for the customer.

If you need additional information on choosing a dent repair pulling system, call Giulio Valle at Pro Line Systems

for a free consultation. Call him at 305-793-9503

Pro Line Systems International is a recognized industry leader in providing auto body repair equipment

to the US and international collision repair industry "Since 2002".

Visit The Pro Line Systems Website