Here's 9 Tips for Purchasing an Autobody Frame Rack

Published by Giulio Valle in Informational · 6 March 2023

Tags: Frame, Machines, Autobody, Frame, Rack, Purchasing, Decisions

Tags: Frame, Machines, Autobody, Frame, Rack, Purchasing, Decisions

Here's A Checklist To Review Before Purchasing A Frame Machine

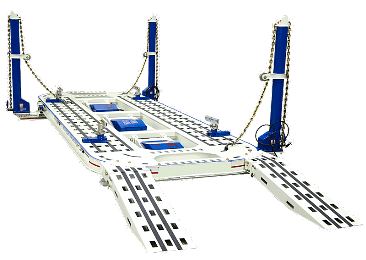

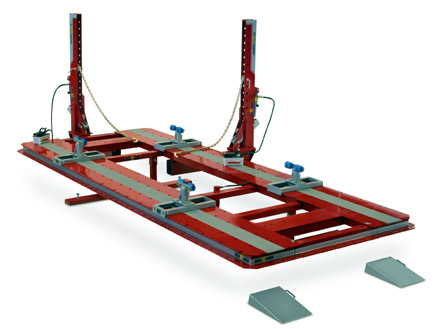

A frame rack also called a frame machine, or frame straightening machine is a vital piece of professional automotive body equipment that securely holds vehicles in place during repair work. If you're in the market for a new frame machine for your body shop, these tips can guide you in purchasing the appropriate frame straightening machine for your needs.

Tip #1: Consider the Vehicle Specifications

When purchasing a frame rack, it's important to remember that different models and brands of frame racks come with varying capabilities that are designed to cater to different types of vehicles. The specifications that you need to look for will depend on the types of vehicles that you work on in your auto body shop.

For instance, if you primarily work on larger vehicles like trucks and SUVs, you should choose a frame rack with a higher weight capacity that offers more anchoring options to accommodate the weight and size of these vehicles. Additionally, work on a variety of vehicles with different wheelbases. You should choose a frame rack with adjustable pulling towers that can be moved to fit different wheelbases.

On the other hand, if you primarily work on smaller vehicles like sedans and compact cars, then you might not need a frame rack with a high weight capacity or adjustable pulling towers. However, you should still make sure that the frame rack you select can accommodate the weight and size of the vehicles you work on.

Tip #2: Consider the Working Heights

Working heights are a critical consideration when choosing a frame rack for your auto body shop. Working height refers to the height at which you can work on the vehicle while it is on the frame rack. This is an essential consideration because it affects the accessibility and maneuverability of the vehicle, which can impact the quality of the repairs you make.

When considering the working heights of a frame rack, it's important to consider the range of heights you need for the vehicles you typically work on. The best models should allow you to adjust the working height to a range of between 12 and 42 inches, though this can vary depending on the specific model of the frame rack. If you work on larger vehicles like trucks and SUVs, you might need a frame rack that can go higher to accommodate the height of the vehicles. On the other hand, if you work on smaller cars, you might need a frame rack that can go lower to ensure better access to the vehicle's undercarriage.

It's also important to consider the length of the frame rack and the length of the pull towers. A longer frame rack can help provide more maneuverability when working on the vehicle, while higher pull towers can help provide more flexibility when pulling and straightening the vehicle.

Tip #3: Consider Your Shop's Specifications When Selecting a Frame Rack

While choosing a frame rack that can handle the specifications of the vehicles you work on is essential, it's equally important to ensure that the rack can fit comfortably within your body shop. Before making a purchase, take the time to measure your shop's dimensions and compare them to the specifications of the frame racks you're considering. You'll want to ensure that the rack you select fits easily within your shop, allowing ample space for maneuvering around the vehicle during repairs. By considering your shop's specifications, you can select a frame rack that is well-suited to your needs and a good fit for your work environment.

Tip #4: Look for Models with Minimal Dead Zones

- A True 360o machine that is capable of positioning pulling towers anywhere around the rack is essential.

When selecting a frame rack, it's important to ensure that the frame rack you choose can fit comfortably within your body shop. This involves taking into account the physical dimensions of your shop, including the height, width, and length of the work area, as well as any other equipment, walls, or machinery that may be present.

Before purchasing a frame rack, it's important to measure your shop's dimensions and compare them to the specifications of the frame racks you're considering. This will help you determine whether the frame rack you're interested in will fit within your shop and allow for adequate space for maneuvering around the vehicle during repairs.

In addition to measuring the dimensions of your shop, you should also consider the layout of the work area and the workflow of your shop. For example, if your shop is small and has a narrow work area, you might need to choose a frame rack with a narrower width to fit comfortably. Suppose you have multiple technicians working on different areas of the vehicle simultaneously. In that case, you might need a frame rack that provides ample space for maneuvering around the vehicle and working comfortably.

Tip #5: Look for Models with Multiple Anchoring Options

When purchasing a frame rack, looking for a model with various anchoring options is essential. The anchoring system is the primary way the frame rack secures the vehicle in place during repair work. Different vehicles require different anchoring options, and having various anchoring options on the frame rack can help ensure you can work on a wide range of vehicles.

Some popular anchoring options include pinch weld clamps, chain or strap anchors, and wheel clamps. Pinch weld clamps are the most common type of anchor and attach to the vehicle's pinch welds, while chain or strap anchors connect to the vehicle's undercarriage. Wheel clamps attach to the vehicle's wheels and provide a secure grip. Some frame racks come with all three anchoring options, allowing you to choose the best option for the specific vehicle you're working on.

When selecting a frame rack, make sure the anchoring options can accommodate the types of vehicles you work on, including heavy-duty trucks and SUVs. The frame rack should also provide flexibility regarding where you can attach the anchors, allowing you to repair any part of the vehicle. By selecting a frame rack with multiple anchoring options, you can provide the most secure hold for the vehicle, reducing the risk of damage and increasing safety during repairs.

Tip #6: Choose a Model with High Weight Capacity

When purchasing a frame rack, it's essential to select a model with a weight capacity that can handle the vehicles you work on. The weight capacity is the maximum weight the frame rack can support, and exceeding this limit can cause damage to the rack, the vehicle, or both. Therefore, it's crucial to select a frame rack that can accommodate the heaviest vehicles you work on, including trucks and SUVs.

The weight capacity of a frame rack is determined by its construction, including the materials used, the size and number of hydraulic cylinders, and the thickness of the steel. Some high-end models can handle weights up to 18,000 pounds, while others may only support up to 10,000 pounds.

When selecting a frame rack, consider the weight of the heaviest vehicles you work on and ensure its weight capacity can handle them. Also, remember that the weight capacity includes not only the weight of the vehicle but any additional equipment or accessories that may be attached to it during the repair process.

Tip #7: Consider the Ease of Use

When selecting a frame rack, it's essential to consider its ease of use. This refers to how easy it is to set up and operate the equipment, including the controls and maintenance requirements. Choosing a frame rack that is easy to use can save you time, reduce the risk of errors, and increase your productivity during repairs.

Some of the factors to consider when looking for a frame rack that is easy to use include the following:

- Intuitive controls: Look for a frame rack with straightforward, easy-to-understand, and operating controls. This can help reduce the learning curve and minimize the risk of errors during the repair process.

- Simple setup: Choose a frame rack that is easy to set up and take down, with clear instructions and minimal equipment required. This can save you time and help ensure the frame rack is used correctly.

- Maintenance requirements: Look for a frame rack with minimal maintenance requirements, such as easy-to-replace hydraulic lines, cylinders, and straightforward cleaning instructions. This can help reduce downtime and increase productivity.

- Accessibility: Consider a frame rack with accessible controls and anchoring points, making maneuvering around the vehicle during repairs easier. This can help reduce the risk of errors and increase safety during the repair process.

Tip #8: Check for Durability and Warranty

When selecting a frame rack, it's important to consider its durability and the warranty that comes with it. A frame rack is a significant investment for an auto body shop, and choosing a model that is built to last and comes with reliable support is essential.

Durability is a critical factor when selecting a frame rack. The equipment should be made of high-quality materials, such as heavy-duty steel, to withstand the weight of the vehicles and the force required to make repairs. Additionally, the frame rack should be designed to resist corrosion and other forms of wear and tear, ensuring that it remains in excellent condition for years to come.

Another important consideration is the warranty that comes with the frame rack. A good warranty can give you the peace of mind that you're making a sound investment and have reliable support should any issues arise. When selecting a frame rack, look for a model with a comprehensive warranty covering parts and labor. Ideally, the warranty should last at least several years and provide prompt service in case of a breakdown.

Tip #9: Look for a Reputable Brand

When purchasing a frame rack, selecting a reputable brand that produces high-quality equipment is important. Many frame rack manufacturers are on the market, and not all of them are created equal. Choosing a well-respected brand with a proven track record can help ensure that you're getting a reliable and durable frame rack that will last for many years.

The Star A Liner Cheetah 360 Is another American Made Brand At Economical Prices. CJ Inc. Manufactures both the American Freedon and Star A Liner Cheetah 360 Brands at their Minnesota plant since the early 80's.

Here are some reasons why it's essential to look for a reputable brand when selecting a frame rack:

- Quality: A reputable brand is more likely to produce high-quality equipment, as they have a reputation to uphold. Their products will likely be made of better materials, with greater attention to detail, than lesser-known brands.

- Support: A reputable brand is more likely to offer excellent customer support, including technical assistance, replacement parts, and maintenance services. This can provide added peace of mind and ensure that any issues with the frame rack are resolved quickly and efficiently.

- Availability: A well-known brand is more likely to have a broad network of dealers and distributors, making it easier to find replacement parts and receive service when needed.

- Innovation: Reputable brands often invest heavily in research and development, resulting in new and improved models with cutting-edge features that can help increase productivity and efficiency.

Pro Line Systems International Inc. is a highly reputable distributor of auto body repair

equipment technology "Since 2002".

Contact Pro Line Systems for a free consultation, they have a vast offering of quality tools & equipment

for the modern collision repair facility.