Self Piercing Riveting In The Auto Body Shop "Explained"

Published by Pro Line Systems in Body Shop Equipment · 12 April 2022

Tags: Self, Piercing, Riveting, The, Modern, Car, Body, |, gyspress, 10T, |, Pro, Line, Sytems

Tags: Self, Piercing, Riveting, The, Modern, Car, Body, |, gyspress, 10T, |, Pro, Line, Sytems

Self Piercing Riveting The Modern Car Body

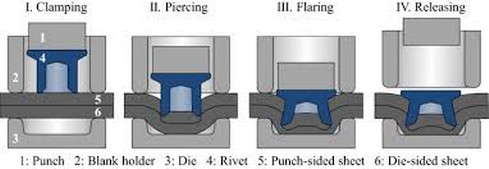

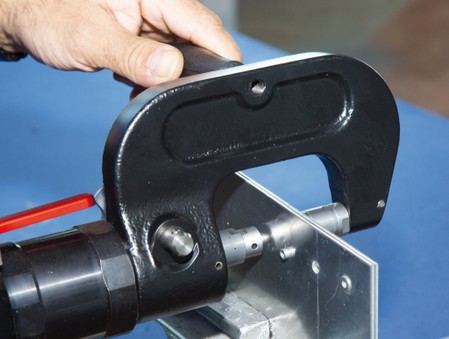

If it hasn't occurred to you yet, that the process of self-piercing riveting has entered the world of modern auto body manufacturing and repair, hang in there and we'll help catch you up quickly.Self Piercing Riveting is a single-stage riveting process for sheet metal and many other types of material that doesn’t require pre-drilling holes.Self-piercing riveting (SPR) is a very efficient method of joining sheet materials using a specially coated tubular steel rivet that pierces through the various layers of sheet metal without piercing the final layer, and this is where the magic begins.As the pressure from the rivet gun pushes the spr rivet through the metal sheets, the last layer of metal gets pressed into a receiving die with the rivet spread firmly into the final layer forming an incredibly strong clinch.Conventional riveting using solid metal rivets requires drilling holes, but with SPR no pre-drilling holes are required, making it a Fast single-step process. This procedure has been tested vigorously and has proven to outperform spot welds.Typically, the first sheet is pierced when the rivet is inserted. Then, the second sheet is deformed into a tightly compressed clinch that resembles a button when the rivet is pressed into it.In certain instances when the rivet gun C-Arm cannot get access to the rear of the panel then there is no other option but to use Blind Rivets. Ex; GYSPRESS 10T Self Piercing Rivet Gun.It Works Like ThisThe metal sheets are clamped between a die and a rivet holder, usually magnetic. The rivet is then driven through the sheets using a Self Piercing Rivet Gun, which pierces the top sheet causing the lower sheet to expand into the die. The shape of the die causes the rivet and the lower sheet to flare outwards, forming a mechanical interlock.The rivet head will be pressed flush with the top sheet but the bottom sheet will always protrude in a button-like appearance, which is Not Pierced.The implementation of self-piercing rivets requires semi-tubular rivets, although solid rivets or Flow Form rivets are also sometimes used.Always Follow The Vehicle Manufacturers Repair Procedures.Unlike welding, self-piercing rivets can be used to join dissimilar metals or non-weldable materials. This is becoming increasingly important in the automotive industry where a mixture of aluminum and steel panels is being used. Self-piercing rivets are, therefore, being used instead of spot welding in an increasing number of vehicle designs.SPR is an effective way of joining parts made from any combination of aluminum, steel, plastic, or composite.Other advantages include no fumes and sparks, no heating of materials, low noise, resistance to rust and corrosion, and low energy consumption. It’s also suitable for use on pre-coated materials that are difficult for welding.If access to the rear of the panel being joined is not possible, then the repairer must use Blind Rivets as the joining method. Again, repairers Must Follow the latest repair procedures published by the auto manufacturer.This is an example of the latest advancement in Self Piercing Rivet Guns.This model is very popular in auto body shops around the world.Every Shop Needs OneThe GYSPRESS 10T (Ten Ton) Self-Piercing Rivet GunOur Number One Selling RiveterCome on over to the Pro Line Systems Web Site And Watch The VideoLearn more about this #1 Selling Category Leading SPR Riveter and how you can purchase oneSpecial Promotion On Now... Check Out The Deal...

Call us for pricing and availability at

FYI: Hey, Curious about Giulio Valle, the Authoritative Author, and creator of this Blog and the

Pro Line Systems Website? Check Out Giulio's Interesting Brief Biography Here